Fatigue test ISO 7206-4, 6 and PI-58 (ISO 7206-8)

Normative References

ISO 7206-4: Implants for surgery – Partial and total hip joint prostheses – Part 4: Determination of endurance properties and performance of stemmed femoral components

ISO 7206-6: Implants for surgery – Partial and total hip joint prostheses – Part 6: Endurance properties testing and performance requirements of neck region of stemmed femoral components

PI-58 (ISO 7206-8): Implants for surgery – Partial and total hip joint prostheses – Part 8: Endurance performance of stemmed femoral components

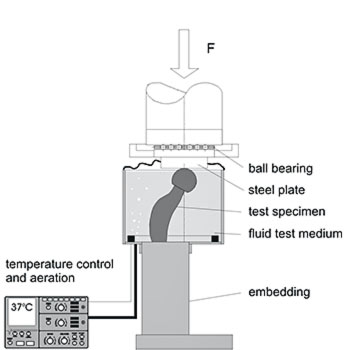

The fatigue test according to ISO 7206-4 simulates the dynamic loading of a hip stem during gait. Proximal loosening of the stem is presumed to simulate worst case conditions and replicates clinical failure. Load inclination, embedding level, load level and number of cycles are given by the test standard. The test conditions do provide safety information about fatigue failure of hip stems by a simplified model.

ISO 7206-6 simulates a well ingrown stem. Fracture (if any) is expected to occur at the neck region of the stem.

The alignment of the hip stem versus the test load is straightforward for simple hip stem geometries but may be challenging for anatomic stems. EndoLab® has developed a 3D CAD based method to design custom AM-printed jigs for sample alignment.

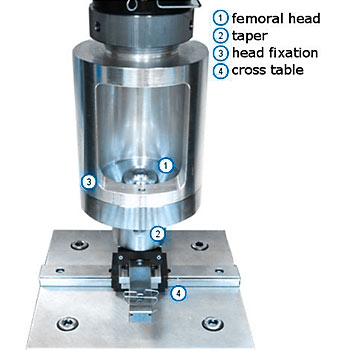

The maximum test frequency depends on the flexibility of the stem and the performance of the test equipment. EndoLab® developed special tools to embed the stem correctly (see Fig.) which ensure constant loading of the implant. Most of our tests are performed using MTS® or Zwick® test equipment.

Femoral head torsion test ISO 7206-13

Normative References

ISO 7206-13: Implants for surgery – Partial and total hip joint prostheses – Part 13: Determination of resistance to torque of head fixation of stemmed femoral components

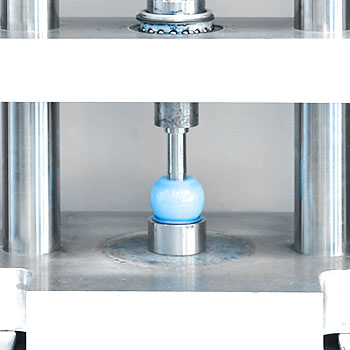

A modular fitting between ball and stem is subjected to torsion loading until movement occurs. Amongst others, the loosening torque is determined. Special care is necessary testing ceramic balls: Due to the high torsional moments, small flats may be required to fixate this component.

Femoral head compression test PI-14 / ISO 7206-10

Normative References

ISO 7206-10: Implants for surgery – Partial and total hip-joint prostheses – Part 10: Determination of resistance to static load of modular femoral heads

ASTM F2345: Standard test methods for determination of static and cyclic fatigue strength of ceramic modular femoral heads

PI-14: Compression Test Hip Ball static/dynamic

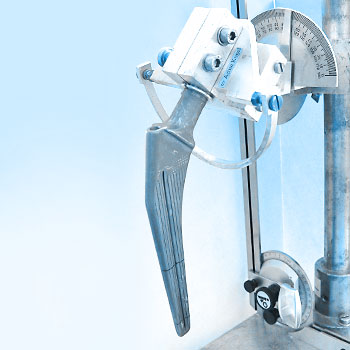

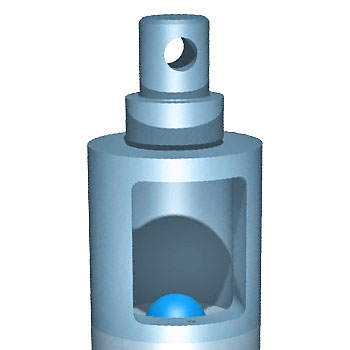

The modular connection between the ball and the stem of a hip endoprostheses is loaded until failure. The ball is placed on a conical bore with a copper ring to ensure an even load distribution. Fatigue testing of ceramic head systems is also available at EndoLab® in an internal procedure PI-14 and meets the requirements given by ASTM F2345 as well as FDA guidance documents.

Pull-off testing according to ASTM F2009 and ISO 7206-10 is possible and described in Ball Pull-off tests ASTM F2009.

Femoral Head pull-off test ASTM F 2009

Normative References

ASTM F2009: Standard Test Method for Determining the Axial Disassembly Force of Taper Connections of Modular Prostheses

ISO 7206-10: Determination of resistance to static load of modular femoral heads

These tests are performed to establish the force required to disassemble taper connections of modular prosthesis. The standard ASTM F2009 is applicable amongst others for partial or total hip or shoulder prostheses (there is an upcoming ISO standard). ISO 7206-10 describes the method to establish the tension load to disassemble modular head systems.

Luxation test PI-3

Normative References (internal)

PI-3: Luxationsversuch ohne Schaft-Pfanne Kontakt (akkreditiertes Verfahren)

Hip endoprostheses tends to luxate in a cranial direction. Some of the known factors enhancing luxation are known:

- A: cup inclination

- B: cup movement due to loosening

- C: accident

- D: insufficient refixation of the trochanter major

- E: bone contact

- F: release of capsule or muscle

- G: squeezed bone cement

- H: short neck / offset

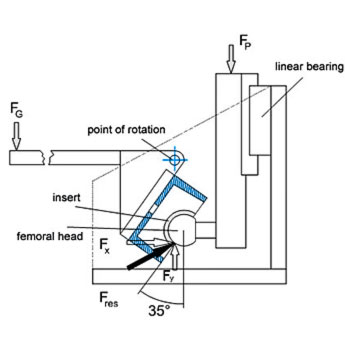

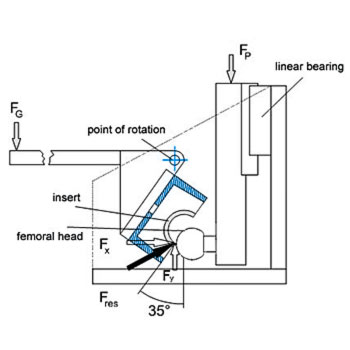

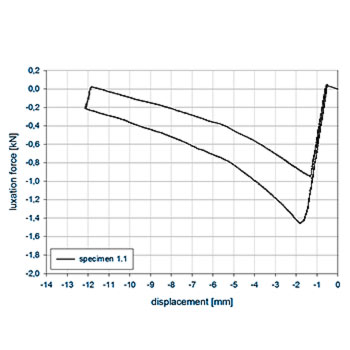

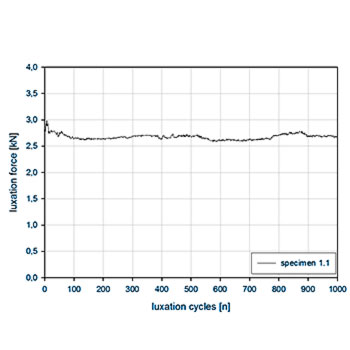

Due to mechanical reasons, luxation only occurs if the resulting load R moves across the luxation point or impingement of cup and stem occurs. Luxation due to extensive release of muscle or capsule tension is not simulated in this test. Most cases of luxation have multiple causes as classified above. Aim of the tests performed by EndoLab® is to gain information about the resistance of a modular insert as well as about the resistance to abrasive wear (hard/hard couplings!). The luxation due to impingement and without impingement are simulated using two different test setups.

The procedure can be performed up to several thousand luxations/repositions using loads up to 3 kN.